Hey there, fellow DIY enthusiasts! Ever found yourself staring at your socket wrench set, puzzled by the two different socket types? Don’t worry, we’ve all been there. Today, we’re tackling the age-old debate: 6-point sockets vs. 12-point sockets. Let’s unravel the mystery and equip you to choose the right tool for the job!

Understanding the Contenders: A Closer Look at Socket Types

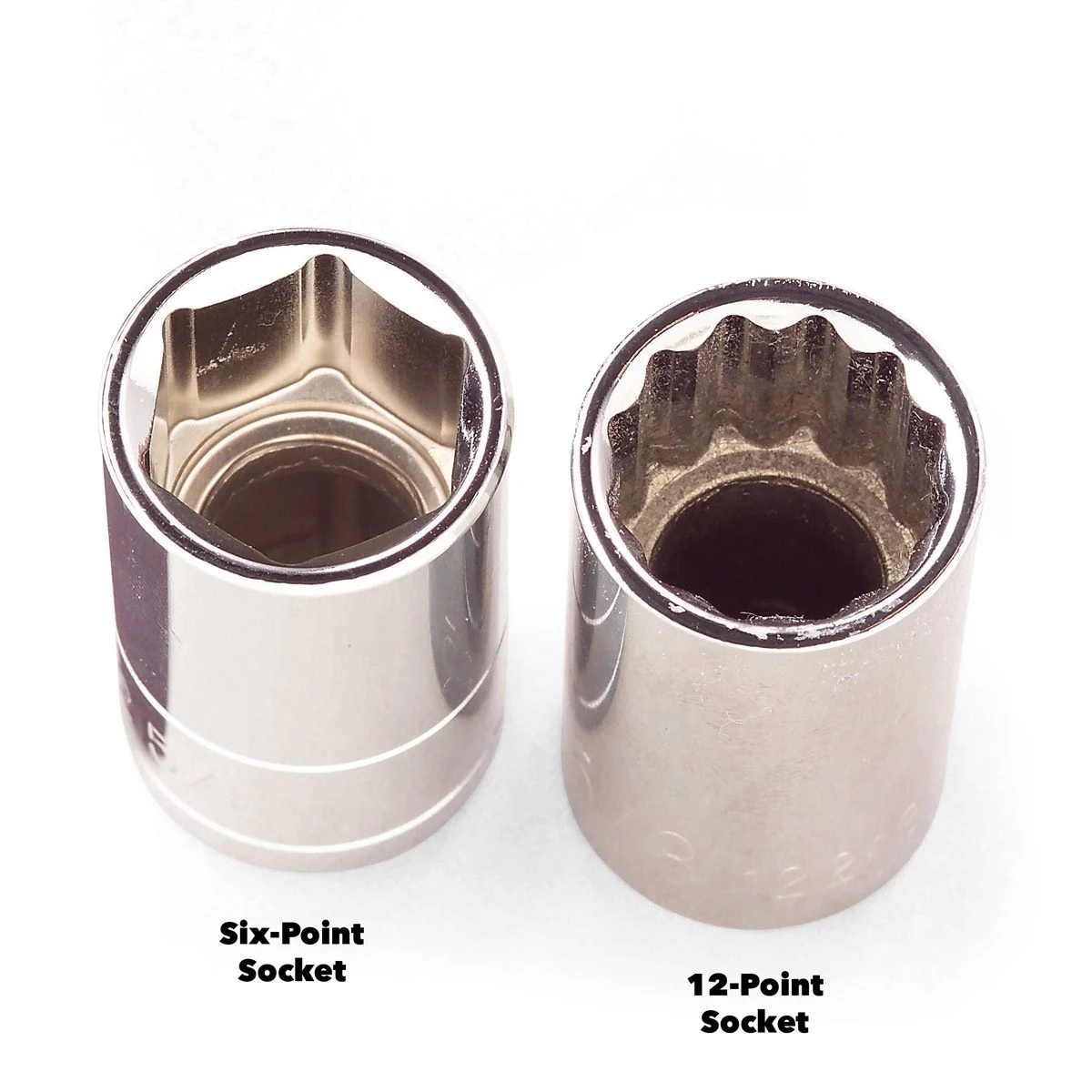

Before we dive into the pros and cons, let’s get familiar with each socket type:

1. The Trusty 6-Point Socket

Picture a standard hexagon – that’s your 6-point socket. Six points, evenly spaced, forming 60-degree angles. This design isn’t just for looks; it provides:

- Maximum Grip: The socket’s points dig deep into the fastener’s corners, providing a secure grip and reducing the chance of slippage, especially under high torque.

- Strength and Durability: The thicker walls of 6-point sockets make them incredibly robust, perfect for heavy-duty tasks and loosening stubborn bolts.

2. The Versatile 12-Point Socket

As the name suggests, this socket boasts twelve points, creating a double hexagonal shape with 30-degree angles. This design allows for:

- Increased Accessibility: The double hex configuration means you have twice as many gripping points, making it easier to fit the socket onto fasteners in tight or awkward spaces.

- Flexibility: While not ideal for high-torque situations, 12-point sockets are suitable for lighter tasks and situations where perfect alignment is challenging.

The Showdown: When to Choose Which Socket

Now, for the million-dollar question: which socket reigns supreme? Well, the answer, like most things in life, depends on the situation.

Reach for the 6-Point Socket When:

- Torque is King: Dealing with large, stubborn fasteners that require significant force to loosen or tighten? The 6-point socket’s superior grip and strength make it the champion in these scenarios.

- Preventing Damage is Paramount: The secure grip of a 6-point socket minimizes the risk of rounding off fastener corners, a common frustration with 12-point sockets under high torque.

- Working with Standard Fasteners: The majority of fasteners you’ll encounter in everyday DIY projects are six-point, making the 6-point socket your go-to tool.

Opt for the 12-Point Socket When:

- Space is Limited: Working in tight quarters where maneuverability is key? The 12-point socket’s multiple gripping points make it easier to engage fasteners, even with limited rotation.

- Visibility is Low: In situations where you can’t get a clear view of the fastener, the 12-point socket’s forgiving design allows for quicker engagement without needing perfect alignment.

- Dealing with 12-Point Fasteners: While less common in general DIY, if you encounter a 12-point fastener, the matching socket is a must-have.

A Word of Caution: Chrome-Plated Sockets

Most quality sockets feature a chrome plating for rust prevention and easy cleaning. However, over time, this plating can wear down and flake off. Always inspect your sockets before use and discard any with peeling chrome, as the exposed metal can be sharp and dangerous.

Beyond the Basics: Additional Factors to Consider

Choosing the right socket goes beyond just the number of points. Here are a few additional factors to keep in mind:

- Socket Drive Size: Ensure the socket’s drive size matches your ratchet or wrench handle. Common drive sizes include 1/4″, 3/8″, 1/2″, and larger for heavy-duty applications.

- Socket Depth: Sockets come in various depths (standard, deep, extra deep) to accommodate different fastener lengths and positions.

- Socket Material: Chrome vanadium steel is a popular choice for its strength and durability. Impact sockets, designed for use with impact wrenches, are made from even tougher materials like chrome molybdenum steel.

Resources for Further Exploration:

- Family Handyman: https://www.familyhandyman.com/ – A treasure trove of DIY tips, tricks, and project ideas.

- Popular Mechanics: https://www.popularmechanics.com/ – Your go-to source for all things mechanical, from cars to tools and technology.

- This Old House: https://www.thisoldhouse.com/ – A trusted resource for home improvement advice and inspiration.

The Final Word: Choosing Wisely for Project Success

Understanding the strengths and limitations of 6-point and 12-point sockets empowers you to tackle any DIY task with confidence. Remember to assess the specific demands of each job, choose the right tool for the task, and always prioritize safety. Happy wrenching!